| Contact Rob – signs2008@hotmail.com |

| The Journey |

| Why did I want a Bedford ? – I have always loved the look, I bought a white one stock standard around 1996. I loved it, so did the kids, I used it to take the crew surfing up and down the coast. My daughter drove it to school and her friends thought she was cool. I eventually resprayed it, and she shone, I was offered money for it a few times over the years.

Destroyed by fire.

Unfortunately it was destroyed on Xmas day 2001 when the south coast was hit with devastating bush fires, the poor girl, it was a sad day. - Since then I have always had the desire to get another. |

|

|

| Why now? - 15 years later.

I have turned 60, my days of surfing are behind me, the family has grown and moved off to raise their own families, leaving the missus and I with some time….We just went away on a trip sleeping in the back of the Commodore station wagon for some of it – we loved it - we came home all enthused to get a camper van, I mentioned it to my mates, who are all classic car enthusiasts and have been on my case to get myself a project, I also mentioned I liked Beddy’s and that was it, they got more excited than me, I was a little scared as I’m no mechanic and mechanicals are scary things, but they all assured me they would help and nothing can’t be fixed or modified… the hunt was on and so here we are now.

I eventually found one in Wongawilli, a young bloke had bought it as a project, but other things came up so he decided to shift the old girl on, he had spent many months trying to find one without much rust, which saved me a lot of looking as he managed that just fine. It came from Vico originally and might have been an Australian post van, apparently she was used to carry eggs before she was retired…. |

|  From the front - Cads, Steady and Cusso’s cars. From the front - Cads, Steady and Cusso’s cars. |

| The plans. |

| What am I going to do to her? well not a lot…I'm to old for tricked out punk vans and complete custom jobs…I have always just loved the way they looked straight off the shelf, I might do a few mods, thing that will improve the running, stopping and comfort, I may do a very subtle graphic. I have done plenty of airbrush work in the past, but generally It will be pretty subtle.

|

|  My last airbrush work on the boot of a 65 Ford… |

| Ultimately she will be used for drifting around the country side on short trips…who knows…time will sort all that out, when you reach this age it’s a day by day proposition. |

| Pick up the old girl - 11th July 2015 |

| Cad’s and Cusso came on the run to pick up the old girl, she was sitting on a property at Wongawilli looking pretty sad, surrounded by long grass and old abandoned houses, the fellas helped load her on the trailer and brought her back to the South Coast at Woollamia.

|

|    |

| First look |

| 12th July.

The first close look revealed she was in pretty good nick, most of the body panels were reasonably straight, the inside paint was brand new, with one fairly major ding in the front drivers guard, The passenger side had been stripped back to bare metal and undercoated…that’s going to need some attention as the weather has gotten to the thinner areas with fine mild surface rust poking through – the drivers side rear quarter had been repaired before and they must have sprayed the undercoat and left it exposed before the top coat was painted as the paint is pealing and cracking - The drivers window was all over the place and didn’t work. There was some rust as expected in the lower panels but nothing showing in crucial spots, Beddy’s are well known for their rust, so who knows what will be found once the work begins.. |

|

|

| Into it. |

| 13th July

Next day I was into stripping out the inside seats, old metal cargo barrier, motor cover and old timber floor panel’s their pretty basic in construction, so dismantling is a relatively relaxing job… |

|   |

| I stripped out the old floor coverings and this revealed some small rust holes, nothing major, and an easy fix – a good wire brush job, some rust converter and she was looking pretty good to start with. |

| The Shed - a home for the old girl. |

| Now before I start work on any body work or mechanical, the old girl needs somewhere out of the elements to rest her weary bones, so a new/old shed will have to be built.

The Kiwi.

How fortunate, a few days before I’m about to start the shed I receive a call from a young Kiwi mate coming back from Germany looking for somewhere to crash for an unspecified amount of time…he happens to be a carpenter, and his first words are, “"do you have anything you want built while I'm there’'”…”silly question” |

|    |

| The old shed had been there for 30 years – held up with a few sticks and a prayer, I have used it to do my graphics in…I'm a signwriter and graphic artist. So we slung the new part built out of mostly reclaimed timber and iron that’s been laying about the property for years, to the old part. My mate Stapo “ head of the Woollamia Speedy building company” turned up with a dirty great beam which allowed us to rip out the old back wall opening up the whole are. We had the shed all built and ready for the Beddy in about a week and a half. I threw some old lino and rubber mats on the dirt floor, built some shelves and was given an old steel work bench that fitted perfect, a few tubes of silicone completed the weather sealing - and pushed the Beddy into her new home - we have just been through some major flooding, the worst rain in 30 years and it didn’t leak, - the old girl was looking happier. |

|    |

| Body Work |

| August.

Time to start the journey in earnest, a closer look revealed lots of superficial body damage…, The side opening door was the worst, it’s a common problem with the door being subject to swinging open and slamming against the side mirrors and the so called “bump stop”.

The body work for me is pretty enjoyable, so getting stuck into that was fun. After a few days at it between other commitments it was showing signs of coming together, once you start you just keep finding things,,,small depressions, small dings pushed from the inside…all good though and easy to repair.

I'm not going nuts on her, she won’t be a show car, just enough tho make her tidy.

The lower regions have some rust holes….that’s a bit more of a challenge as i can’t weld for shit, but that’s where mates come in, and i have great crew of mates who are into classic cars and have heaps of experience, and are willing to help… |

|    |

| September - early

The body work is progressing - all the superficial dings are just about squared away, the major dent in the front drivers guard has been pulled out and teased back into place. The front screen is out revealing some surface rust but pretty dam good otherwise. that won’t take much to square away. |

|

|

| I made my own dent puller out of bits hanging about and fashioned some dolly’s out of an old boot-makers anvil. worked a treat….by the time it was done the panel was pretty straight and required a small amount of fill…

Told you a was a shit welder.

Puller made from old plumbing fittings, continuous thread, and a steel screw,

Dolly’s made from an old boot maker anvil were great for the panel beating.

|

| September – mid

Work has been progressing between other commitments, my policy of trying to do a least one thing a day where possible is working, my policy of not rushing and giving myself a headache is working, so the journey is still enjoyable.

I stripped the paint off the join between the roof and the gutter – not one bit of rust, all looked great, that was a huge relief. |

|  |

|  |

| The Motor

September - late

The one thing I’m defiantly not is mechanical, so this part of the journey is a full learning curve for me starting at the bottom.

As advertised the old girl “ Started – Stopped – and Ran” - but that was about all. She ran pretty rough and blew heaps of smoke, suggesting what? like I said I’m a numky when It comes to mechanics – so Cusso came over,,, he’s a bit of a whizz, engineer and all that. First thing lets check the compression – in this part of the journey we found a broken spark plug, stuffed points and the dizzy was pretty much rooted…but some tweaking by Cusso had the old girl purring like a kitten, – well not quite but at least it was idling and responding to some pressure.

The compression was pretty good but down on one cylinder.

My mate Steady turns up as Cusso is about to leave after his good work.

Steady is a whizz mechanic of all things as well as professionally. He and Cusso confer like too old doctors and Cusso leaves. Steady arrives carrying a complete gasket set and decides it’s a great time to pull off the head. – My fears start to rise! - “No worries mate, It will only take 30 minutes” – 50 minutes later covered in crap and the heads off and on the bench….time for another beer!

A quick look and it seems ok – Steady says - “I have the means to pull out the valves and springs etc, lets do that”

OH SHIT OK I GUESS.!

|

|     |

| The Verdict. |

| Not good, but not to to bad…one of the valves is buggered and so is the seat…no amount of honing is going to fix that |

|  |

|

A new head is required, everything else looks ok, the pistons look good with no movement…

Steady leaves after a few beers and dinner, giving me instructions on how to clean the water from the block, drain the oil and empty the tank.

Cleaning the block etc – what a bloody shit of a job – in this case the old girl has thick oil everywhere, mixed in with red dirt, making an almost cement like glug, suggesting she may have been out west for some time…hence the lack of rust…who knows? - Red back webs full of egg sacks abound.

The water from the block came out like brown lava, spraying me everywhere, a few showers later see’s me looking pretty clean again, other than the fingernails – they look like I have been a mechanic all my life – all good fun.

|

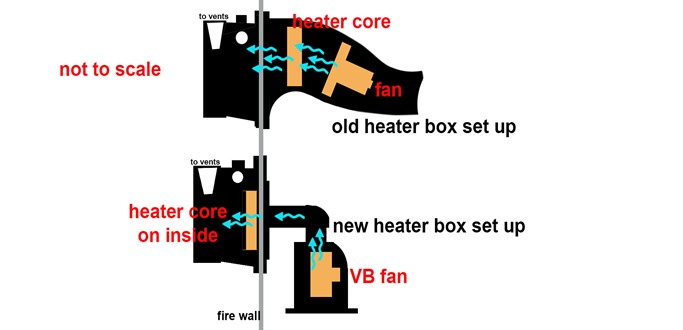

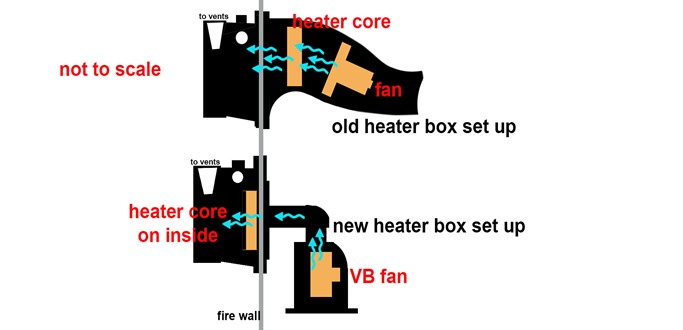

| Heater dismantle.

The heater when turned on made some horrible noises and sounded strained. I pulled it out and it was filled with a rats nest, they had used some stuffing as the nest and packed it in nice and homely, the fan motor looked dodgy and wouldn’t spin freehand, I dismantled that,,,cleaned out the crap, lubed it up and whoo ee!,, she spins like a top

quiet as a mouse with heaps of blow. – but the heater core is totally rooted – rusted and falling apart…

Options have to be considered! |

|  |

| The nightmare window glass realignment puzzle.

Now that was fun – I’m lying, it was painful and frustrating, the glass was out of it’s track and all over the place…I tried to realign it but all attempts failed…take a blood great deep breath – further inspection which I should have done straight away – learning by ones mistakes - revealed the small T Piece neoprene spacers that align the window in the mechanism were shot. I had been trying to do it without removing the whole mechanism – a mistake – I took the whole lot out, an easy job, pulled it apart, an easy job, went and snavelled one of my wife’s neoprene chopping boards and went to work fashioning myself a couple of new T Pieces – must say it worked a treat – put the mechanism in and carefully replaced the window using timber wedges to stop it falling inside the door…replaced the track that someone had unscrewed and let drop to the bottom of the door, which I only realised was there after taking out the mechanism. and “woo bloody hoo” ! the thing works almost as smooth as new…don’t know what the long term outcome of the T Pieces will be but for now at least it’s working fine. |

| Bucket Seats

Eddy (Foreskin) don’t ask!

has given me a couple of decent bucket seats – when he get’s a chance he will come down and fabricate the bases for those and do some welding – another whizz. |

| Weekend distraction.

Sept 26-27 |

| Spent the weekend in Sydney helping Foreskin with his project – here are a couple of pics, One of his mates turned up in another FJ, this one had a V6 Commodore engine and other mods.

Working on Foreskin’s car just made me anxious to get back to the old girl… |

|  |

|   |

| Dash Board.

Sept 29th 015

With my policy of trying to do at least one thing every day where possible, today I took the instrument panel out of the van – after taking off the back cowling it revealed a huge wasp nest made out of mud wrapped around the wiring harness some of the wires were corroded and others snapped right off their connections….it was a total mess….

|

|

|

|  This is just some of the nest – I should have snapped a pic before I demolished it, but I was up to my ears in it by then and keen to finish what Id started. |

| My plans for the dash.

I’m intending to build my own using new instruments and getting the whole lot rewired…Can’t be that hard can it ?

I’m going to make the dash emulate the original but in a 50’s –60’s style. stainless steel, resin, padding and paint.

Looking forward to starting that…something like the concept below – but not these colours ? |

| |

|  |

| October 11th 2015 |

| LET THE SPARKS FLY |

| Saturday – Foreskin ( like I said “don’t ask! ) arrives, he finally had a chance to get down the coast to do some welding, Fortunately there isn’t much rust to cut and weld…just a few spots on the usual areas, along the bottom of the side door, back lower corner panels and a couple of spots near the rear of the guards…all small holes and reasonably easy to do..

It still took a few hours with myself following Foreskin around grinding the welds flat, then slightly depressing the wounds in preparation for the fibreglass fill.

We finished off the day with some of the FIFO Gang under the stars, a B.B.Q and of course a few beers to the sounds of Rockabill coming from the Moonshine Room…

|

|  |

|

Thanks Foreskin for your great work. |

| The head saga continues.

After finding out one of the valves and seat was shot, I was given another head for free, it proved to be worse than the one I had, then the opportunity for a 161 fully reconditioned for nothing came to me, but I decided not to go this way, as I'm loosing what power I have….then a 202 with electronic ignition became available, it came out of a young blokes Torana - well! - I can only think that it might have had some punishment as I know the blokes he hangs with.

So what now?

For now I have decided to stick with the 173 – get the head reconditioned, or investigate getting a new Yella Terra head, either way it would be done so i can run unleaded petrol, at least I don’t have to pull out the motor. |

| |

| Front Spoiler.

While I have been waiting on other things to develop, decided to play around and make myself a fibreglass spoiler. whether I use it is still up for discussion and thought,, I had the materials on hand so why the hell not have a play around… |

|  Early stages – still stuff to add and vents to cut out – I'm not sure if it’s the right thing…time will tell. But it was fun to do…Foam, Ally panel and fibreglass.. Early stages – still stuff to add and vents to cut out – I'm not sure if it’s the right thing…time will tell. But it was fun to do…Foam, Ally panel and fibreglass.. |

| October 15 - 2015 |

| Cads Project |

| Got away from the Beddy and went and visited my mate Cads today - “arrrrrr! - the frustrations”, and I was thinking I had taken on to much, ha..no chance, - Cads has decided to put a bigger engine in his Caddy, this endeavour has led onto all sorts of other resto problems. Cads will have it sorted very soon then it’s off to the engine fitter and on the road again.

|

|  |

|  |

| October 19th 2015 |

| Not a great deal has been happening

Unfortunately I have been away working in Sydney, thank god I don’t live up there anymore! - anyway!, since Foreskin did his welding magic I have, (when the chance arrives) been squaring away his handy work. Most of the fill is done and sanded and undercoated - I have been covering any exposed metal with primer and am about to attack the windscreen area….but first a trip to the Rock and Roll festival at the Entrance called ChromeFest, lots of classic cars, Rockabilly bands and sights to behold. Probably no Beddy’s though, wish there was, as i haven’t even seen a live one for many years. – funny thing is mates have been seeing a few around the area. just not me. hopefully they know what there looking at.??

Once that’s over I will get stuck into the screen area.

Here are a few progress shots.

P’S - If there are any Beddy owners travelling down the South Coast near Huskisson, feel free to let me know…Id love a chat. - details below. |

|  The screen needs some attention, but not much. |

|

Priming. |

|

|

| October 28th 2015 |

| Not one Beddy!.

Just returned from a rock and roll festival on the Central Coast. Hundreds of Classic cars and hotrods, thousands of hours and dollars involved in the restorations, cars and trucks and bikes of all types, but not one Beddy, I will hopefully address that situ next year., haha! - probably get run out of town!! - hehe..,

Grille out.

Came home all inspired to get stuck in, so today with a couple of hours to spare i ripped off the grille and support bar, going to take them to the local chrome guy tomorrow for a quote…took off the break booster and attachments and rubbed the crappa out of the engine bay = this created heaps of room to work, reckon I could pull the motor out through there without to much trouble – maybe?

Also played around with another simpler spoiler concept…more inclined to go this way if at all….one never stops playing and thinking does one!

The Beddy dilemma, SO MANY OPTIONS!

|

|  |

| Also squared away one of the weld patches. That was the biggest piece of rust in the old girl so not to bad for a 37 year old lady. |

|  |

| November 5th – 2015

Rain Rain go away.

If this rain would bloody stop Id finish spraying the primer…ahhhhhhhhhh!

Diff feedback.

I have been hunting for info regarding the best and easiest way to do the Diff thing!

the alternatives so far are.

1 - An early Chevy Impala diff. – still trying to find out details, almost impossible to find.

2 - A HQ Holden sedan diff – have to get the rim cut and re-welded inside out to accommodate the extra width, but are left with two different stud patterns leading onto more changes….

That’s what I use to have in the original old girl….it was a pain in the butt having two spare wheels to carry around.

3 - An AU falcon sedan diff – change the short axel to a long axel to get the extra width I need – have to get my head around that one, and are left with the above problem.

4 One of my mates had a HG Holden diff in his – probably the same as a HQ really - So not sure about that alternative – more info needed.

5. get the Beddy diff centre changed via cutting and welding the original axels onto a different highway diff…..sounds expensive…Ill let you know! At least Id end up with the same wheels all round….

Gavin Davies - Rob,You"re looking for info on Diffs - I'm not sure how a 6 would handle it but I have an 8 with a 9"diff with a 2.7:1 ration, purrs along the highway at 1700rpm @100kph a comfortable combination

Wheels

Gavin Davies - Rob-contact Exclusive tyres they're the American racing wheel agents,they purpose built mine with the specs I needed and did the hole spacing to match, took about 12 weeks from the USA but worth the wait

|

| 4th November 2015.

The Ignition.

Live and learn.

went to move the old girl and the steering lock was stuck on, tried fiddling with the key and this eventually broke.

so my next adventure was to get the ignition mechanism off – simple enough me thinks, except the apparent bolts down the centre have been sheered off…tried to drill them out…broke two drill tips and didn’t make a dent…got onto the BUGA forum and asked for help! Gunning and Marishka both gave me valuable suggestions. trouble was I didn’t quite understand the answers correctly. |

|  |

| Marishka - “Yeah when fitted at factory the screws sheer at the heads when fitted.

I just use a 4 " grinder with a 1mm disk and cut a slot across the screw,

Then use a flat screwdriver to get them off.”

Gunning -

“I recently had to do the same on my Subaru, I had trouble trying to cut slots in the bolts as it was still on the car, I ended up using a punch and hammer to start bolts turning, then could use fingers to turn, I replaced with a standard bolt, make it easier next time”

So I'm still thinking its just the centre bit that has to come out, tried all and sundry and still no luck, so I cut the whole thing off with the grinder, only then on closer inspection i found out the whole shinny part was a bolt and not just the smaller centre bit…so for anyone having a go check out the pics they should explain what I'm trying to say.

New door locks.

My new door locks arrived from England this week – so that will be an interesting little project to tackle as well.

Master Cylinder oil container.

My new / second hand, oil container arrived from the banana state this week as well – their rare as hens teeth and I was lucky enough to find one on fleebay…

|

|

I did put a cut in it as suggested, but then tried turning the very small centre bit with a small screw driver instead of a large one that would have turned the whole bloody bolt.

One step forward - one step back.

|

| The Motor

Well after much procrastination I have finally secured myself a motor, it’s a 202 with electronic ignition already attached, apparently only driven to church on Sunday’s by a old nanna.

Now this means only one thing! - getting the old girls front end in the air – this should be fun! - stay tuned.

Motor arrived – looks decent so far.

The usual oil, nothing a clean and some new paint wont fix , took the rocker cover off, looked a lot cleaner than the original 173 – no glug,

Next step to replace the gaskets and get her in the beddy..

Water pump – appears to be brand new.

Even the ignition coil looks in great nick.

|

| The Motor

Yes the motor again – Steddy hit the shed this arvo, I slapped a Fat Yak in his hand and we both got stuck into it.

We throw it on the engine stand, after the last 173 pull apart and the 179 rusted heap, I wasn’t going to get to excited about this motor.

But..after pulling the valves out and checking the rest visually, it’s looking pretty sweet, no rust, valves all good and ready for a clean, pistons clean as a whistle, chambers free of any corrosion, so fingers crossed this should be the donk for the old girl to get her purrrrrrring again. |

|  |

|

|

|

Despite being old and decrepit, Steady does a good job, I’m learning heaps Old school rules apply, take 6 valves out and have a beer, take another 6 valves out and have another beer.

The septic Tank.

Now after a couple of Fat Yaks Steady needs to get home, Google is waiting.

Me - Steady, when you turn be careful you don’t hit the septic tank it sticks about 6 inches out of the ground.

Steady – Yeah no worries – see you tomorrow - he throws a u-turn in the dark paddock and runs straight over the Septic Tank. |

| Polishing the head.

24th Nov 2015

Steady arrived this arvo armed with a small air driven head polisher and went to it – of course the apprentice “me” didn’t get a go, bloody hog, he’s like a spoilt kid that won’t share his toys!

It came out great and here are some riveting shots showing the frantic action. |

|    |

| That’s Steady hogging the toys.

. |

| 28th November 2015

I have lapped all the valves- Steady polished the valves and she is ready to be re assembled and installed. |

| 30th November 2015

Getting ready for the motor removal.

I put an extra beam through the shed and an extra brace to accommodate the lifting of the front of the old girl…it should be well and truly enough to carry the weight…I reckon it would have been ok with the one hardwood beam, but the other hardwood beam was donated, so up it went…probably better safe than sorry….

I’m into stripping down all the connecting bolts etc next week…yee ha…can’t wait to get under the old girl…

My poor old offsider “Steady Eddy” has pulled a muscle in his back, so he is laid up at the moment,,,so progress on the motor has stalled….until he’s able to bend again…

|

| Dash update.

Well my initial idea as can be seen above, has gone out the window…tried it. didn’t like it….so now i have done some carving and some aluminium fabrication and totally changed the whole way I was going about it initially…just have to epoxy the high impact styrene with a couple of layers of 6 oz matt and clean it up and give it a spray or even cover it in vinyl…to be determined.

Anyway here are some shots at the almost fabricated epoxy undercoat stage….

colour and finishing to do of course. |

|   |

| Has a very slight retro feel, and i have always loved ‘curves” and the old girl has curves, so couldn’t help myself…

|

| December 5th 2015 |

| The Motor.

Bugger me, finally had a chance to strip the motor down, I spent considerable time cleaning every part.

We had to replace a leaking main seal around the crank as the old rope seal was pissing oil – off with the balancer. all went well. almost! |

|  I asked - “Steady give us an action shot!” this is what we get – very riveting! I asked - “Steady give us an action shot!” this is what we get – very riveting! |

|  |

| We took out the crank to replace the old seal and cleaned all the bit’s – learning more. |

We flipped her over and started on the head re-assembly

We replaced all the old leaking gaskets with new, we then started to put the head back together, set the torque wrench to the right setting for the head bolts and proceed to break two,,,fortunately there was still some stud showing so that was an easy fix. after closer inspection we could see why, some of the old bolts looked warn and fatigued, we replaced them with the best from the old 173 engine and all torqued up fine. all good until another bolt broke…a closer look showed more wear, but only on the middle ones, “WHY? - Steady - because that’s where their exposed to the water jacket”. OHHHH!! I’m learning!………

So now we just have to do the sump side of things. |

|   Corrosion on bolts from exposure to water. Corrosion on bolts from exposure to water.

. |

| Anyway all went well from there, new seals, new gaskets, we cleaned her down, dried her off and proceeded to spray her with the high temp engine paint – “Randy Red”

|

|  |

| Header score.

10Dec 2015 |

| Scored myself a set of headers and some exhaust from a rusting wreck not far from our property – the rusting heap has been there for quite some time, so i thought id have a look at what it had to offer…the rest of the ute is totally rooted, but low and behold it had what appeared to be a decent set of headers and exhaust pipe including a muffler.

I bought them home and cleaned them up and there as solid as!….a quick steel brush job. some rust converter and their ready for a coat of stove pipe black… |

|  |

|  |

| Motor stage, whatever.

The old girl has been readied for the front end lift, all the connecting things have been disconnected and the bolts loosened…I made a gear box trolley out of some old roller skates I have been hanging onto for years, despite the constant harassment of - ”you know who! - “throw them out ‘'” their rubbish, what will you ever do with those?” – you get the drift hey fellas!…. |

|  |

|  |

| Wiring. |

| 30th Dec 2015

I made the decision to re do the whole wiring – after finding corrosive wasp nests from one end of the car to another most of the wiring was pretty shot.

I ordered a Universal 22 Circuit Wiring Harness Kit, by Procomp Electronics, reading the blurb it seemed like it would handle the job.

”Advertising Blurb” It’s a bit long winded but worth a read if your considering buying anything that comes from Procomp Electrics. “Procomp Electronics Universal Automotive Harnesses can be used in just about any vehicle where basic or more wiring is needed. Ample wire lengths make this kit especially suited for everything including trucks with long beds and extra cabs heaps of wire, enough for a large tray truck, clear instructions, anyone can do it!! Yeah right, the kit came incomplete, on inspection we found connections coming apart which would lead to problems down the track, the wires to the back weren’t long enough to reach the lights, plug in connections that didn’t match anything, parts missing, no rubber grommet for the fire wall, no main fuse, no brake light wires, being an American wiring harness we came to the conclusion that they wire their brakes through their stop lights, - but we don’t! - so you would think they would have provided the right wires for Aussie regs…”very poor” , no wiper washer wiring, . to say we were disappointing would be an understatement, I wish Id done a bit more homework. Update.

9th Jan 2016

The manager of Sydney Speed Supplies ran me about the negative review on their eBay site…I outlined all the probs…he seemed surprised by what I had to say, he was very apologetic and offered to do something for me to make up for the problems…his main concern was the negative review and what we could do to change it off the site, I told him I was willing to say that he had made and effort and had at least tried to address the situ. But! - He then sent me a reply for me to upload onto eBay essentially saying Id made a mistake in giving it a bad review…

[ speedmasteraus is requesting that you revise the original Feedback you left for Universal 22 Circuit Wiring Harness Kit (191623837873). Reason for request:

You confirmed to the seller that you had accidentally left the wrong Feedback. So essentially he just wanted me to take the blame for them supplying a sub standard piece of equipment that would cause nothing but problems for anyone silly enough the buy one…like me…

I was trying to do the right thing by this supplier as i relise he is a middle man, but after seeing this request where they take no responsibility for what they are peddling, I'm leaving my original review on the eBay site…

The solution.

Luckily I had my son in law coming down for a xmas break – he’s a whizz at wiring, A sparky - he installs complicated communication and computer systems into large buildings and is in the process of doing his own car project.

Steady came over for the day and with his valuable assistance and some head scratching, and some purchases at the local MOTO store to stock up on missing parts, the wiring is finally making good headway.

If i was doing it again Id definatly source from a recognised loom company, but persistance prevailes and where getting close.

http://www.ebay.com.au/itm/191623837873 – this is the link to the offending item.

I contacted the supplier and he showed concern by directing me to another supplier. Guess he’s just the middle guy making a few bucks, so no real concern to him. I haven’t followed it up any further, other than sending him a review I intend to post on his ebay site..so if this is what your intending to do, be a bit wiser than me and do your homework.

Result.

Well after some initial hickups the wiring is in and ready to hook up to the verious components….

I wasn’t ready for Ben, but couldn’t let the oportunity to get it underway slip by while he was here…now the next step is to buy all the guages and switches and get the dash sorted….

Guages.

6th Jan 2016.

I have ordered a Dolphin 5 Gauge set from Parts for Hot Rods located in Queensland – hope this experience with ordering off the net is better than the last.

In the mean time I have sourced some switches and been playing with the dash.

it’s all in undercoat at the moment and will be pulled apart and painted once I decide on the final design…

here is a shot of the progress so far, bit of a retro feel….why not I say!.

The gauges arrived this morning and i went about fitting them in to their position in the dash….they look pretty good…seem like a decent set, nice and clear and not to big, and they add a bit of bling….the whole thing is just sitting there at the moment, now time to work out the fixing.

The lighter grey area is where Im thinking the radio will sit…?

Still some switches to add.

For all those interested, I will post some images soon of the process I went through to create this dash…

I still have some ideas regarding an overhead consul, these are things I can do while Im waiting on the mechanical side to move forward…

The Mind has been working overtime…everyone who comes into the shed has the same question…”what colour are you going to spray the old girl ”?…….I like curves so this is what Im thinking….but theres a while to go so I may change my mind by the time it’s ready to do…Satin black back…Gloss black front….with a dash of colour thrown in…. ha…sounds like an exotic drink.

|

| Dash Update.

29th Jan 2016

Bloody hell the years pumping by.

Anyway been busy with Christmas and Family stuff but managed to do a few things.

The Dash is just about squared away – all the elemnets are in other than the stereo. Finally figured out how to fix the top part of the dash with secret bolts – the top has had 2 coats of epoxy and one coat of 6oz polyester resin all over – been filler coated and sanded and a fine roughened texture added, just have to finalise the painting once it stops raining.

Here are a couple of shots of the dash construction.

”High impact foam” for the carved top.

Has to be layed up in Epoxy as Pulyester resin will disolve it..

Blinker Mechanism.

Bought a new wiper blinker arm from T.R Spares in Padstow – it’s out of a “Series 3 Landrover” and is exactly the same as the original for $75 delivered – “Thanks Wendy and everyone else for their advice from the Bedford Community” - Great people.

I have a HZ steering Column that I may put in at a later date.

|

| Roof lining |

| Having family down over christmas and the multiple tourists we name “the plague” decend on the poor village of Huskisson, combined with the constant breaks in the good weather with rain, it’s been a bit slow on the Beddy restoration.

I also lost my best mate. my dog Sasha over the last week – A sad time felt by the whole family, knocked the wind out of me…she had a good life and a decent run to the age of 16, she is burried under a tree next to the dam in the back paddock…R.I.P Sash.

But on Monday I made the decision to do a new roof lining for the cabin area as the old vinyl one was stuffed.

I decided to do it out of fibreglass in one piece, over the last few days it’s all but finished, all I have to do is line it with something, that hasn’t been decided upon yet…

Here are some progress shots.

The Process for those that might be interested.

Stage one – make an accurate template out of cardboard, in this case a freezer box scrounged from Harvey Norman…thanks Harvey!

2 – lay up a single layer of 6 oz fibreglass, in this case chop strand as that was what I had on a flat smooth sheet of laminate treated with surfboard “wax in styrene” to act as a release agent.

3 – now you have a flexible but reasonable strong sheet of glass, mark out the outline off the template and cut the shape out, as it’s only thin a stanley knife did the job easily without mess.

4 – Floppy test fit – all good.

5 – Make some accurate templates of the curves in the roof, cut out those templates and lay the sheet over them and weight the sheet to conform to the shape. I started with the biggest curv at the back corresponding with the strengthening rib in the van across the roof behind the driver position.

.

Back has already been shaped to the template laying on the table in front, by laying up strips of glass.

6 – Time to lay up some strengthening strips of glass to make the sheet conform and hold the shape.

This process was repeated for the side curves until the shape was self supporting.

7- I cut some alloy angle as can be seen below, to form a reinforcing rib and a fixing mechanism to the formentioned strut behind the driving position. This was pre fitted to the roof rib, then glassed onto the sheet. fits like a glove.

The alloy angle cut and bent to conform to the shape and glassed onto the head. The alloy angle cut and bent to conform to the shape and glassed onto the head.

8 – more strengthning ribs were added and the front above the screen was reinforced to make the shape sit flat across the front as can be seen in the pic

here you see the front about to be strengthened, thereby flattening in the process as the previous strengthening rib process had caused the front to have a few small wobbles – but this will take that away and make it sit flat. here you see the front about to be strengthened, thereby flattening in the process as the previous strengthening rib process had caused the front to have a few small wobbles – but this will take that away and make it sit flat.

9 – A stiffening and supporting rib was made by overlaying 3 to 4 layers of matt down the centre. this should be all that is needed to stop any sag – probably not needed as the structure was bloody strong anyway…

You can see the strengthening and anti sag supporting rib layed up down the centre as well as the other strengthening and supporting strips.

I used a hot mix for the resin. for those that don’t know, a hot mix is adding extra catalyst to make the glass go off a lot quicker - so the whole process was fast..

Now all have to do is line it with something and it will be done – fitted like a glove on the first try so pretty happy with that…

Looks pretty sweet when fitted.. can’t wait to line it…

then add some sound deadening and insulation above for a snug as a bug fit.

Contemplating a simple roof consul next – and thinking of doing the door cards the same way.

Oh yeah! over xmas I worked on the dash, all undercoated and ready for the final colour choice.it’s still missing the polished alloy bling, that wont go on until after it painted.

|

| Dash

8th Feb 2016 |

| Decided on doing the dash grey and white – not real adverturous I know, but i can always change it.

|

|  |

|  |

|  |

| The Head Lining.

14th Feb 2016 |

|  Bought some black velvet like material from Spotlight, it was on special, dirt cheap, and lined the roof panel, Finished the centre roof console, it houses a swivel light setup from a ford, covered the lot in vinly and test painted the vinyl – laquer paint sticks like anything,,,so painted some red for drama, mixed with the grey and white, the black roof liner makes it all pop,,,the white is sign panel a plastic aluminium rpe painted gloss panel. easy to cut, light and rigid,,,,eventually going to line the back out with this material… Bought some black velvet like material from Spotlight, it was on special, dirt cheap, and lined the roof panel, Finished the centre roof console, it houses a swivel light setup from a ford, covered the lot in vinly and test painted the vinyl – laquer paint sticks like anything,,,so painted some red for drama, mixed with the grey and white, the black roof liner makes it all pop,,,the white is sign panel a plastic aluminium rpe painted gloss panel. easy to cut, light and rigid,,,,eventually going to line the back out with this material…

fun stuff, |

| Door Cards

15th Feb. |

| Attacked the cards today the same way as the roof lining,,,but a lot easier and esentually their flat with one little annoying change of direction towards the top.

Step 1. make up a door template care of Harvey Norman again.

Step 2 . cut some chop strand matt….Id normally use woven for flat layups as it lays down better and the finished side is smoother, but I was given a roll of chop strand so Im using that.

Step 3, wet it out, I used a cheap Bunning pink wooly roller, cut down to match a small 4 inch roller arm…I get 3 out of a 2 dollar roller and trow the lot away after use. This time I layed up two layers for a bit more stiffness.

Step 5, Once dry cut it out, test fit and prepare for that annoying little kink in the panel.

Step 6. score the panel with a knife almost through, and carefully put the kink in.

Step 7, make up a couple of kink templates and clamp the sheet to make it conform to the kink.

I have a possum in the wall of my workshop scratching itself right now, bloody annoying little bugga - I have a possum in the wall of my workshop scratching itself right now, bloody annoying little bugga -

anyway where was I. ?

Step 8, layup another layer of matt over the kink score marks.

Step 9, Cut the shape out using your template.

I have made fake stained glass panels using this techinque, and this is generating some ideas for the back..the thinking never stops does it!

Step 10 – thats still to come – some reinforcing to do in a few areas and try to come up with a design for the panel. |

| Roof Ribs.

20th Feb 2016

Being as Im stuck at home because we have a 1000 bloody bikeriders going past our front gate all day, they have decended on Huskisson for the Huskisson leg of the Australian Triathelete Series, and our road is used as the bike leg… mmmmmmmmmmmm…stay calm.

Anyway back to it.

I have used the time to make myself some ribs.

I liked the result of the front cab area roof so much I have decided to do the roof in the back the same way.

But it will need supporting ribs as the gaps are to wide for the fibreglass to span without excessive glass.

I didnt want to run length way timber battens as I have seen other do, I want the lining to curve with the roof at the sides and blend into the wall lining, when I get around to doing that.

So I decided to make some fibreglass ribs that match the existing steel ribs in the old girl.

I won’t bore you with the process as I have done that above already…but escentialy it’s the same process.

Made the timber form and popped out all the ribs in about 4 hours so quite a quick process. Now some fiddling to do to get them in sweet..

Timber mould sealed in release wax and resin and I applied some vasso as added help to help get the layed up glass out of the mould.

|

| Easy job and I have test fitted the first rib and after some adjustment to length by taking out a bit in the middle and using that oportunity to lay up some reinforcing on the join which will stiffen the whole rib, it fitted like a glove.

test sitting in place but still some finishing to do

|

| Distractions. |

| Huskisson had it’s annual White Sands Easter Parade over the long weekend and some of the gang had their cars in the mix. Hopefully next year the Beddy will be there with all the other Fifo gangs cars.

She Bird and Cusso had their sweet red award winning T.Bird leading some of the old classics down the street.

|

| Door Cards. |

| While I have been waiting for some of the major things to get off the ground I have been playing with some of the little enjoyable things.

I put together the door cards…using silver/grey upholsterers material and used some red vinyl on the top where your arm is to save dirt on the material.

I put a bit of aluminium tubing across the door for some bling and to match the dash…Im going with a cabin area of black, grey, and red, with a dash of white here and there,,,the back who knows?…the outside who knows, I keep changing my mind.. |

| Arm Rests.

I shaped up some arm rests out of polyurethane, threw some glass over them and padded the top. |

|  |

|  |

| |

|  The black on the door is photoshopped because the door is still orange as below at the moment….i will be using The black on the door is photoshopped because the door is still orange as below at the moment….i will be using

satin black on the inside, not gloss. |

|  Door off – ready for painting. Door off – ready for painting.

Test fitted the buckets now Cusso is going to do some special fabrication at his leisure so they sit sweet.. Test fitted the buckets now Cusso is going to do some special fabrication at his leisure so they sit sweet.. |

| Front End troubles. |

| |

| Well old Steady Eddy who has been suffering from post shoulder surgery blues, finally had some time to direct me into action taking the front end apart…all good until we get to one of the wishbone sections and find one is well and truely seized and refuses to release…the other side almost fell out..

A bench full of bits. A bench full of bits.

Then to make matters worse the long shaft threaded on both ends that goes through the frame is rock solid and won’t come out of it’s inner tube…..after much swearing and me taking a nice chunk out of Cads knuckle, ‘I didn’t feel a thing” we gave up until I can find someone with an oxy to apply some heat… the before mentioned sleave will be pressed out…

The offending wishbone bit – no idea what they call it? some sort of sleave. The offending wishbone bit – no idea what they call it? some sort of sleave.

The offending shaft – no idea what they call this either – I gave it a few names i can’t repeat though… The offending shaft – no idea what they call this either – I gave it a few names i can’t repeat though…

And Cads gave me a new name I can’t repeat after whacking his knuckle and taking some bark off!!

But it’s all good, still on a steep learning curve and still enjoying the journey… |

| Roof Lining |

| April 6th 2016

Been pluging away at the interior - I finished gluing the black material to the f/glass panels and screwed them up…made up some trim cover strips between the ribs, think they look ok, just have to finish the half circle cover trims along the outer edges…and the roof lining is just about all squared away…other than the cab area the rest of the van interior will be a lot lighter in colour to make it brighter inside..

Cusso is working his magic on the seat bases for the buskets…can’t wait until i get them in and fitted…

|

|   |

| Door Card |

| Finished the passenger door card, different shaped holder on the door to accommodate more things for the passenger.

maps etc.

Have to concentrate on getting rid of all the orange from the van next… Have to concentrate on getting rid of all the orange from the van next… |

| Seat mounts |

| My craftman mate Cusso and his able side kick the Pest have been busy making my seat bases…stoked to see the progress on facebook…can’t wait to see them live and fitted…Id have done them but I can’t weld for shit…and Cusso is the man when it comes to doing fiddly fitted projects….

Thanks you pair….greatly, greatly, appreciated.

And to Chrispy and Twisted for donating the seats to the Beddy rescue – thanks a million.

|

|   |

| Gearbox. |

| Im going with a trimatic which I have secured from another Beddyfile way up in the hinterlands of Byron Bay.

It’s suppose to have been reconditioned 5000 k’s ago and built strong, so Im hoping that will do the trick, my daughter and hubby did a day run down from Brisbane to pick it up and will bring it down when they come down to finish off the wiring…..

I picked up a couple of Torque Converters and a flex plate cheap from Callala Bay a suburb on the other side of the bay…so things are progressing….now the big job of doin the whole front end so I can get the motor ready to fit..

|

| Gear Change

looking for a floor shift to go with the trimatic – if you have one hanging around and want to sell it at a resonable price, Id love to hear from you… |

| Roof Lining.

The two back panels are covered, I decided to run a strip down the centre for extra support and to run some

LCD lightings strips as well…should be funky, ha! cover strips are in and test fitted, fit fine…. |

|  |

|  Did some embosed flames to break it up. Did some embosed flames to break it up.

|

| Bucket Seats. |

| “Cusso” the master of all things metal came over today with his trusty helper ‘The Pest” for a test fit of the seat bases he has been doing…he cut and shunt the original passenger side box to make the pattern match….they fitted like a glove forst go. He will now do some final design work and they should be ready to fit soon…getting there…

Beddy’s are the ultimate chick magnet – this one needs a feed though..

|

|  cant wait till that orange is gone… cant wait till that orange is gone…

thanks “Cusso” and his trusty offsider the “Pest”

and of course Eddy and Twisted for giving me the seats in the first place.

|

| Stuck Pivot Pin |

| 22 April 2016

Pulling the front end down was all easy going until one of the pivot pins refused to budge, it was rusted fast into it’s sleve and no amount of persuading was having it out. That was until Cusso took charge and worked a bit of his magic, it’s now out! but buggered, and a replacement will have to be installed.

thanks Cusso for your determination and eventual success…stoked!

That’s one long wrench handle…tools of choice – angle grinder, lump hammer, WD 40, stillsons with a meter of heavy pipe attached….every man should have one in their kit. That’s one long wrench handle…tools of choice – angle grinder, lump hammer, WD 40, stillsons with a meter of heavy pipe attached….every man should have one in their kit.

Brought the front end back home and started immediatly into getting all the ball joints etc out – easy job with a press, cleaned, scraped and wire brushed every component, treated with rust connverter, cleaned, epoxy primed and now ready to paint.

Next step sourcing suspension components – still undecided about using either rubber or nolothane bushes, opinion is devided and that doesn’t help the cause….nolothane are cheaper so thats always an arm twister when your on a limited budget, but there suppose to be harsher and can squeek I was told….don’t want that, aHave to hit up the Beddy community for some feedback..

.. |

| 1st May 2016

Front wind shield visor.

While all the above was happening I decided to make myself a front windscreen visor – I sort of like the look, and I use to have a metal one on my original beddy for a while, and it worked well in keeping the sun out. Since Im ratting the van out, I decided Id make my own, out of fibreglass with some added “features” that I wont show until it’s done…thats if it looks ok….if not it will be one for the scrap heap!! ha. |

|

Polyurethane foam – starting to be carved out and shaped.

a way to go yet.

9th May 2016

Well like I said Im having some fun with this project…what the hell…have to put a smle on ya dial some time…

think ill be calling the old girl – Bones from nowon..haha.

anyway whether I use it or not who knows…been good fun making it up anyway…

If you haven’t guessed Im going to rat out the van on the outside…make it like an old signwriters van, but the inside will be customed in a, for want of a better description. “slicker way”. in other words not ratted…

Now the mad push to get the suspension done and the motor in by the beginning of July as my son in law is coming down from Brisbane to finish off the wiring…

|

| Suspension Bushes.

After some positive feedback from the Beddy Community I have decided to go with SuperPro bushes. They seem to have been the bushes of choice for most people.

I will let you know how it all goes soon.

10th May - Ordered = about two weeks away.

Front lower ball joints.

I managed to get myself two lower ball joint for half price of feebay – there Roadsafe products so should be good, the last two he was carrying.

|

| Side Windows.

After much thought I have decided to make my own panels to replace the side windows…Since Im going in totally the opposite direction to what I first said about “not punking out the van” Im to old for that!”….35 years of creating fake scenes and props for a job means I can’t leave ‘Bones’ standard as first stated, …. Im going to have some fun with “ Bones”……I have a couple of ideas and can’t make up my mind about which one I like…stay tuned.

|

| Front engine cradle

has also been wire brushed and scrubbed to an inch of it’s life, single pack epoxy undercoated and now hit with a couple of layers of chassie paint… |

|  |

| |

| Engine Bay. |

| Today I put a big effort into cleaning the engine bay and throwing some black paint on…fiddly job but the bay’s looking good, need to fill some holes later once I have put everthing back.

|

|    |

| Undercarriage.

I have also been removing surface rust on the undercarriage. Plenty of elbow grease required – I have decided to go with a product called Rustbuster - Epoxy Mastic 121 – After much research this stuff seems to get the ants pants award from people that have used it…looked at POR 15 but to many steps involved for such an undercarriage.

This stuff has been extensivly used in all sorts of industries and should fair the Beddy well.

Ill let you know how it goes once I use it..Over this Ill be using a sound deadening coating….Ill let ya know!

http://perpetualcoatings.com.au/ – there in Sydney and their prices are competitive from what I see.

. |

| Bed Base.

While all this other stuff has been happening i went around and saw my mate that makes up Tray Back Campers for some advice on how he does his beds…couldn’t be simpler, CD ply, I made a frame after stripping down some old timber I had to 50 mil square. I made it in two halves and bolted it together so I can remove it anytime easily.

He suggested drilling some holes in the ply base to let the moisture out, It’s what he did when he was constructing yachts and also in his campers…nothing high tech here.

Plenty of room underneath for storage bins. etc.

What a Coincidence - Just now while I was writing up the latest info, Al sent me this image of his rig and said he just sold the whole rig and needs new signs for his new car to come… What a Coincidence - Just now while I was writing up the latest info, Al sent me this image of his rig and said he just sold the whole rig and needs new signs for his new car to come…

traybackcampers.com |

|  |

| Been trying to find shots of the old beddy but no luck – this is the best i have so far, I know I have some, but where? |

|  around 1998 around 1998 |

| Distractions. |

| On top of all this poor old Steady blew his head..After fitting the new head and driving around for some 500 k’s the head blows…poor old dear was not a happy camper…So I went over last night to help console the upset bugga…to find he’s sourced another head off another mate and had stripped it down and started to reassemble it…so all good…so far!….here he is hogging the toys again..look familiar? – before this beddy project I didn’t have a clue about heads…now I reckon I could pull one down and rebuild it with my eyes shut… climbing the learning curve. |

|   |

| Update – 26th May 2016.

Well Cads and Steady came over to help me put the new ball joints, bushes and tie rod ends on etc,,,,all started well we managed to persuade one lower joint in, but ran into trouble with the others…after much swearing, shit bagging, a few payback personal injuries and much laughter, it was decided to have a beer, enjoy some home made vege soup and let Steady take the parts to his work to use his 20 ton press to get them in… |

| Lining the van.

26th May. While all this has been going on, I stripped all my roof linings out and tricky bits, secured any exposed scratches with rust converter, epoxy undercoat and paint, I have then been busy lining the van with some insulation I was generously given by Cusso and The Pest. It was left over from their new work shed erection and they thought of me before disposing of it. After a bit of research the stuff came up trumps with a insulation rating of R5 ansd some sound deadening qualities as wel as human safe. I also lined the back walls and wheel arches with a Butyl product that will help with both the formentioned. I also made some wheel arch covers out of ply, painted sound deadening paint, and lined them with the insulation material as well… It has already made a difference to the sound in the van, just the application of the insulation material glued to the wall deadened the tinny sound when wrapped with you knuckles, and you can hear the difference just speaking in the van… The panel on the right is a mock up of the fibreglass window panels and slots Im going to make. Still some thinking required there. |

|  |

|

|

| I have lined the floor with ply and used the same insulation below that after treating all scratches with rust converter, epoxy undercoat and top coat

I also had a change of idea when it came to the bad base – since I made the wheel arch covers it became easier to make up the bed base using those to support the sides and a simple piece for middle support…way less material and fiddling about to assemble it…

|

| Steady just rang and all the ball joints etc have been assembled and is dropping them over….yeee ha!…Legend! – on the march to getting the old girl back on the ground… |

| Front End

28the May.

Well today it all came together, good mates Cads and Steady turned up to finally get the bits and pieces together.

have to say the front end is like a piece of art…Steady directed the proceedings and Cads and I supplied the muscle and occasionally some inspirational problem solving….only took three beers, lots of laughter and shit loads of bagging and the front end was together, almost – have the breaks, bearings, etc to do, and it will be ready for the motor to be sat in the frame and rolled under the bare front end.

|

|  Steady eyeing off the front end wheel alignment with Cads supplying the grunt. Steady eyeing off the front end wheel alignment with Cads supplying the grunt. |

|  Cads doing some fine tuning to the steering. Cads doing some fine tuning to the steering. |

|  Part of the FIFO crew at work – thanks fellas – where would you be without ya mates – very much appreciated. Part of the FIFO crew at work – thanks fellas – where would you be without ya mates – very much appreciated.

Just waiting on the bearings now – Steady is on the case and after quite a bit of research found out that the original bearings for Bedford are no longer available – so with the skill Steady has he found alternatives.

Those will be fitted this weekend and the motor put in the frame…. |

| Steering column cover. |

| 1st June 2016.

Because I have had to take the original mechanism and give it the heave ho, I ended up with something the normal cover would’t fit…and I didnt have one anyway, so today I made myself a new cover. Timber and fibreglass – I undercoated it tonight and tomorrow at some time I will top coat it and fit it. Took a bit of bugger arsing around, had to allow for the wiring and mechanism movement, but now it fits good. I could use it as a template and throw a mold off it, but I don’t intend on making any more so this will do the trick…and I might change it later anyway if I get tired of it…who knows. |

|   |

|   Just have to make a small soft cover for the mechanism hole and it’s just about done. Just have to make a small soft cover for the mechanism hole and it’s just about done.

Looks ok, simple and as small as I could make it.

|

| Diff recovery. |

| Had the wreck of the HZ layinmg up the back so today we decided to rip out the diff, First off though was to drag the rusted heap of shit over on it’s side….Cads and Steady hooked her up and with a bit of dragging about and reshaping off the bodywork as the rusted panels gave way we dug some holes next the wheels…dragged it into the holes and without to much fuss dragged it onto it’s side…A few beers, a bit of cursing and some more blood spillage and the diff was out and rolling towards the shed…

Now to take the 4 speed box out and the disc brakes off…

The rest will be trashed.

|

|

|

| Interior.

19th June 2016.

While I have been waiting for the mechanicals to unfold I have been playing with the interior – red and black, white with a touch of grey…

Lighting strips to be added soon…all coming along.

|

| Seats

6th July 2016

Another little milestone in the rescue happened this week, I know seats big deal!…but for me it is, Im a complete novice at this type of stuff as cars have had absolutly no interest to me in the past, that was until my first Beddy, but that was a lifetime ago…but this old sheila has me interested, so every stage is just one more step to see her cruising down the road.

And the help from my friends has been amazing, without which this would not not be happening at all.

So this little step was done by my good mates Cusso and the Pest, there a duo on all things,

Cusso designed and put together my seat bases…..taking the old duel seat base cutting it in half then crafting the two pieces back together to match the drivers side…he than cut out the heavy metal support peices to make the new buckets fit the original bases using the old fixing points…..I threw some epoxy and paint over them, with very minimal filling as Cusso’s welding is so good and put the jigsaw puzzel I created by pulling them apart and not marking which bit went where back together, which required a few in’s and outs and some undoing and redoing of nuts…”I will learn one day” - but I got there in the end.

There sitting in position and they fitted perfect. Cusso’s anal bubble as The Pest calls it was spot on….absolutely stoked – can’t thank them enough…

And a big thank you to Foreskin and Twisted for giving me the seats in the first place…another dynamic duo..

|

|   |

| Side Windows and Inside lining

20th July 2016. |

| Been steaming ahead with the windows, after much to’ing and fo’ing, head scratching and drawings i finally made up my mind and went with what I been thingking for ages…Slot Windows, for lack of a better description.

I used Aluminium’plastic composite panels for the overlays, Originally i was just going to glue them in place and make up some clips on the inside to avoid drilling holes around the edges….But I wanted the bolts to show so I drilled out each hole and rustproofed and primed every last one of them…then sikaflexed 227 them into position and used stailess steel nuts and bolts to squeeze them up…I laminated strips on the inside to form a recessed lip around the slots so the perspex/glass had a rebated lip to be glued into…this worked a treat.

| Then used the inside protruding bolts to fit my timber surounds to, killing two birds with the one stone, this gave me something to screw the inside lining neatly to.

I used a super strong silocone adhesive called Soudal to frame the sloted area…let this dry and fitted the inside carpeted ply panels…sweet as….used some bronze 20mm angle around the inside of the slots to trim it up and to help secure the ply snug to the frame…came up about how i had imagined it , so happy with that.|

|

| Aluminium composite panel – pre painted both sides, light, solid and non rusting. this was my first template to give it a try.

I laminated strips around the slots to form a lip inside so the perspex/ glass had a snug rebated lip to sit in.

the Perspex was glued in using window frame sikaflex.

I back sprayed the percpex black where the glue was going to be so it covered the glue from the inside. I then used a window frosted vinyl on the inside, to give me the frosted look…I might change this later…still deciding. very easy to change and repair

|  | Once the panels were all cut and slotted I used Sikaflex 227 to adhere them in position, then used stainless 25mm bolts and nuts to squeeze the whole lot together and give me the bolted on look i was after…

the panels were already strong but with my inside plan they would be solid as a rock.

Im yet to trim the silicone around the panels to make it neat… |  | I framed the inside using timber and used the protruding bolts to secure the timber…I rebated the back of the holes in the timber so the protruding bolts with their nuts didn’t make the timber sit proud of the composite panel.

In this shot the small flat braces are still in place that I used to secure the timber in position around the slotted window forming a frame.

these were removed when the glue had dried. I also insulated the panels with bits of left over insulation material. |  | I used this supertack glue to secure the frame around the slotted window.

I use this stuff in my sign business to fit signs to walls…it sticks like shit and is good outside, inside and on wet and dry surfaces…you would be hard pressed to get the panels apart once this stuff has dried. |  | This is the rebated hole on the inside with the 25mm stainless bolt protruding through and the nut and washer applied…this made the whole thing solid as.. |  | Once i lined the inside with ply, I contact glued the carpet to the ply and screwed it to the inside timber frame.

I like the look – a bit industrial and that will suit the van. |  | Bronze coloured aluminium strips screwed to the inside slotted window sill…this helped to clean it all up and also fix the ply snuggly to the window slot. |  | Slotted windows. | | | |

|  |

|  |

| Motor Transplant |

| 30th July 2016.

This has been a long time coming, we have been waiting a few months for my son in law Ben to be able to get down to do the wiring and to bring the trimatic box Id bought, down from the north coast, The family arrived on Thursday arvo after a 14hour drive from Brisbane, two kids, a dog and my gearbox all packed into the highlux 4x4.

I decided the day before to build an extra bit on the shed with a couple of dirty great hardwood beams so we could hoist the motor aloft….it was suppose to just be a lifting frame but ended up a whole little extension…

The Box.

…it was suppose to be a good box, reconditioned strongly only 5000K’s ago – we pulled off the torque converter and the first thing we discovered was a badly chipped centre gear…oh o! ….so my mate steady wisely decided to investigate further and all the inside bit were stuffed…it was hard to even pull them apart as they had worn ridges right along the splines, there were chunks of metal in the box and the gear thingies were binding which are suppose to slide freely, …I was bummed, the thing is totally rooted.

I was feeling a bit down and my bottom lip was quivering…but the fellas soon had me chippa again – with statements like – that’s customising mate, that’s mechanics mate, you should have seen what happened when I did this and that to their own projects,,,so yes Im not stressing, because me old mate Cads has spent a packet on his project and still has unresolved issues…so wake up to yourself was my own call….,and on with the show.

Anyway, we couldn’t stop here, we still had a motor to fit,,,so that Ben could run the wires to the right points in the coming week before he had to go back to Brisbane…so we threw the old box temporarily back on to help us roll it under the beddy. Lots of josteling around…a few timber blocks a couple of beers each and it was time to lower the body back onto the chassie…this part, with a bit of push and shove, went reasonably smooth….we pulled away the chain block and there she was back on all fours….yeee ha – those 7 months having her nose in the air evaporated.

Did someone say lets have another beer!!!…… bloody oath.

The boys were on a mission to see if they could fire her up if only for a split second…on with the electronic ignition, alternator and the rest,,,fill her up with oil, whack on the extractors Id snavelled off the wreck, rig up the approproate wires temporarily,,,,it was just going to be a quick little hit…battery gerry rigged with a couple of jumper leads, Ben rigged up a conecting wire from this to that….,,,cross the terminals on the starter motor with a screwdriver, hold ya breath….sparks fly, whiring sound……….nothing happens….bugger me the starter motor won’t throw out, a few hits with the hammer,,,still nothing….frustrating considering this starter motor was working fine…

Well it had been a big day and it was time to pack it in….the boys have been there all day, working their butts off, and we have a party tonight around the fire organised…with a few relaxing ales, some dance music, lots of friends to celerate my 40 years and another couples 40 years of marriage. I think Ive served my sentence,,,ya can let me out now!

Overall a bloody great day – the gearbox was a major dissapointment and now I have to go through the whole process of finding another box..be great if money wasn’t a hinderance – id just go out a buy a new one…but that’s not going to happen.

So thanks Steady, Cads, Cusso and Ben for such a bloody amazing effort,,,we had lots of little issues, had lots of fun, but the boys past experience got us to where we are now,,,absolutly stoked with that.

Memeroble moments.

Steady is now sporting a nicely sun tanned right ear. Steady asked to get some light on the subject so Cads puts the 500 watt spotlight right next to his ear…Steady engrosed in what he was doing started to sweat, then the smell of skin cells burning had steady waving his hands around like a maniac, the radiation burns should heal without to much of a scar.

10 minutes later Cads does his other ear….at least the scars will look even now.

The simple 5 minute job of removing a brass sleave in the back of the motor turned into an over an hour job as expert after expert offered their suggestion…lol….more beer…it kills the pain – just ask Steady!

Cads paying out on what Steady decribed as his “expensive high quality American made” gear puller especially designed for the alotted purpose – that wouldn’t work on the above sleave no matter what we did……….only to discover it was made in Tiawan…

We finally got it out with a hacksaw blade, a drill and a cold chissel.

The sure fire old skool compression of grease theory didn’t work either, just sprayed grease everywhere.

Steady having his nuts adjusted a few time when he was under the car with both hands full,,,,the spanner adjustment on his nose. Steady copped a lot off Cads, but what are good mates for!

did I hear you say it was time for another beer. – TOP DAY, TOP MATES.

|

| Wiring

4th Aug 2016

Well the dodgy wiring harness from ProComp Electronics as outlined above has proved to be an ongoing hassle.

Wires in the wrong position, wires not long enough, misslabled wires, inadequate instructions that you need a degree to fathom. As I stated above…save the bucks and get yourself a decent kit…it will pay for itself just in heart ache and time spent..

In the end we downloaded the manual for another more expensive brand of Harness…it was 45 pages long with very detailed illustrations and info that ended up relating to the harness I had pretty well, that was compared with 6 pages of dodgy hard to fathom instruscions that came with the PC kit.

Anyway lucky I had my son in law Ben here, His previous experience and never give in attitude has been invaluable, without it I would have been stuffed.

He has spent three days so far battling with the wiring, a day and a half of that wasted on figuring out the bloody fuse box, rearanging wires….But finally he is well and truely on top of it now.

The Motor itself is all but wired, tomorrow the ignition and blinker stalk will be finished as well as a the added relays and fuses…. |

|  Ben up to his ears in wiring the dash gauges. Ben up to his ears in wiring the dash gauges. |

|  Test lighting the guages. Test lighting the guages. |

|  Back of the Dash. Glad he knows what he is doing, Cause Id be buggered here. Back of the Dash. Glad he knows what he is doing, Cause Id be buggered here. |

|  Still some work to do. Still some work to do. |

| The final stage.

5th August 2016.

Ben surffered but won in the end, there was some confusion earlier but eventually Ben finished 99% of the wiring before he had to jump in his truck on Saturday morning and drive back to Brisbane..

I can’t thank him enough for what he has achieved.

I have a few simple tasks ahead, stop lights, blinkers, radio, overhead lighting etc, but the rest is done and dusted.

.

Ben wrapping up the final piece in the puzzel the blinker stalk. this was solved over a few beers. Ben wrapping up the final piece in the puzzel the blinker stalk. this was solved over a few beers.

Wiper Motor.

We thought the wiper motor was stuffed so I pulled it out and low and behold I shoved it on a battery and it worked fine …..so Ill put that back in and work out which wires go where? |

| |

| |

| Trimatic Gearbox Update.

4th Aug 2016.

Well I have secured myself another box, hopefully it’s going to be better than the last, It’s still in a well functioning Torana at the moment and should be pulled out this weekend…

The fellow I bought the other box from offered to give me the money back, but I wasn’t hastled by that,,,It’s the chance you take….But I appreciate his offer..

Trimatic Update # two. 10th August 2016.

Must have run over a Chinaman – the great soon to be box was in the process of coming out last weekend and someone on thier team forgot to undo one of the bell housing bolts and then applied to much force and the bell housing was shattered….Back to the drawing board!.

Looks like a reco box will be the best option! |

| Distractions.

Recently I did a tailgate signs for a 1927 Chevy truck and Rob bought it around today to show me how it looked. Great truck, and a nice bloke….he bought it 30 years ago as a rusted heap with all the timber piled on top of the chassis. and has spent plenty of time and money restoring it to what it is today..

|

| A bit of bling.

September 15th.

Been a while since I updated…been doing heaps of fiddly bits and interior stuff…..more wiring, finishing off setting the radio up, interiour lights, overhead consol, toggle switches for independent cabin lights, rear lights, etc etc….pulled the brakes apart and am ready to send the cylinders off to be rebuilt with stainless sleaves.

But first the bling! I bought a 5 meter length of LED lights for down the centre of the van both sides of the red flamed overhead panel…they do all sorts of things…glow, pulse, flash, strobe, all in an array of colours…disco lights in the Beddy…stuff me what was I thinking,,,does look pretty trick when there on though…and should put a smile on people’s faces…

purple bling. purple bling.

red bling. red bling.

put in a swivel reading light for the missus and a utilities charger near by out of sight,,, put in a swivel reading light for the missus and a utilities charger near by out of sight,,,

I was given a 12 inch sub and amp and wasn’t going to use it because it was so dam big,,,but after talking to my DJ mate he convinced me the sound would be great and told me to pull the two components apart and put them in seperate…so I found a place for the Sub and the amp…can’t wait to hear the doofff, doffff music, arrrrrg! ….…should go great with the bling lights…struth it’s not getting any better is it! I was given a 12 inch sub and amp and wasn’t going to use it because it was so dam big,,,but after talking to my DJ mate he convinced me the sound would be great and told me to pull the two components apart and put them in seperate…so I found a place for the Sub and the amp…can’t wait to hear the doofff, doffff music, arrrrrg! ….…should go great with the bling lights…struth it’s not getting any better is it!

Must have been all the drugs in the old days! ha….Ill post some pics of that as well once i shoot a couple.

now all i have to do is avoid punching a hole in them – wonder if they sell a cover??? now all i have to do is avoid punching a hole in them – wonder if they sell a cover???

Amp is behind the checkered grill – figured it probably needed some air flow to avoid overheating.?.. Amp is behind the checkered grill – figured it probably needed some air flow to avoid overheating.?.. |

| Side Cupboards.

I also built a side cupboard and mounted one speaker and a couple of openings as well as a top shelf…I have since done the doors, I didn’t want hinges as they break to easy so I worked out a way to hold the doors on without hinges……..an easy solution and works a treat, just a chrome dome nut done up to finger tight locks them in snug as.

|

| Gearbox.

It’s been decided – Im getting the dud box I bought from Qld reconditioned…so at least buying the box gave me something to get fixed up, which will be the best and safest option anyway, so that worked out a resonable investment afterall..… |

| Beddy Art |

| After saying I was to old to punk out the van…well guess what…I just can’t help myself…graphics are in my DNA and the Beddy is a blank canvas…So as you can see I have been test fitting the bonnet and grille and added a bit of art…and some modelling…sun visor and spoiler…I redid the skull on the visor. didn’t like the first one…